www.sumitomo.com.vn

NHẬP KHẨU VÀ PHÂN PHỐI XE NÂNG SUMITOMO MỚI, CŨ TẠI VIỆT NAM

Email: info@sumitomo.com.vn Điện thoại:0904 615 638

QuaPro-R design concept: Space saving The mast structure, retracting range, and device layout have undergone major revisions while ensuring the wheel base and the cabin space of the previous. A minimum right-angle stacking aisle width of 2,340 mm (compared to our previous models: -130 mm) has been realized [*8FBR15C model ].

The major improvement in turning radius performance realizes: the increase in productivity (in-company increase of 33%), decrease of fatigue levels (in-company decrease of 20%) due to turning operations, and increase of warehousing efficiency (in-company increase of 10%). QuaPro-R supports our customers in greater efficiency of the logistics operations.

QuaPro-R

Electric Reach Forklift Trucks

(Compared to previous models)

Work efficiency increase of 33% (compared to our previous models)

The decrease in right-angle stacking aisle width enables a large reduction in steering-turn operations when stacking and removing loads from racks in a warehouse, reducing the cycle time for entire operations.

[*8FBR15C model]

(JIS D6202:2011 in-company test value occurring in operation cycle pattern)

|

I8FBR15C (260Ah) |

33% |

|

Previous in-company models |

0% |

Smooth turning and small, facile turning radius

Minimum right-angle stacking aisle width of realized.

(Achievement of -130 mm compared to our previous models)

| 8FBR15C (260Ah) | Previous in-company models |

| 20% | 0% Reduction of fatigue levels |

Fatigue level reduction of 20%

I (compared to our prevision models)

The reduction in right-angle stacking aisle width largely reduce the steering-turn operations by the operator. Unnecessary operations are minimized to enable reduction of operator fatigue levels.

[*8FBR15C model]

(JIS D6202:2011 in-company test value occurring in operation cycle pattern)

The smooth, small turning radius movement of the QuaPro-R, is designed after a ripple pattern and displayed graphically on the vehicle’s step and waist pad.

Ripple pattern

Previous in-company model use

Image shows warehouse rack area comparison with new and old models

Warehouse/storage efficiency increase of 10%

(compared to our prevision models)

The reduction in right-angle stacking aisle width enables better utilization of storage space in a warehouse. Increasing the number of rack is made possible by narrowing the aisle width which allows larger volume of storage.

[*8FBR15C model]

* 30 m x 16 m warehouse assumed

QuaPro-R design concept: Energy saving QuaPro-R is the first reach-type forklift model to adopt IPM motor which is a drive motor. In addition, we pursued thorough high efficiency, such as revising adopted parts like the AC motor for load handling operations, - reducing the vehicle weight, and optimizing the layout of devices and each type of control. Low power consumption level that tops the industry has been achieved (compared to our previous models: 24% decrease). Reductions in power consumption cost (24% decrease) and CO2 emissions (356 kg decrease/year), and prolong of operating hours (+approx. 2 h/day) are realized. Together with the improved efficiency of the working environment, we will offer our customers an eco-friendly materials handling environment. [*8FBR15C model ]

Energy

[Photo: 8FBR15C/folklift with high-back support]

Qua Pro

Electric Reach Forklift Trucks

Reduction of power consumption cost A reduction in power consumption cost of 24% compared to our previous models has been achieved by reducing power consumption. [*8FBR15C model] (JIS D6202:?011 in-company test value occurring in operation cycle pattern)

| 8FBR155 (280Ah) | 8FBR15C (260Ah) | Previous in-company models |

| 25% | 20% | 0 |

Saving

Eco-friendly energy conservation

Power consumption cost reduced 24% compared to previous models.

(* Value is for 8FBR'l5C. 8FBR15S achieved 25%.)

| 8FBR155 (280Ah) | 8FBR15C (260Ah) | Previous in-company models |

| -371 | -356 | 0 |

| Reduction of CO2 emission amount | ||

The calculation of the CO2 emission amount is based on the new and old models performing the same operations (operational limit of workload for previous vehicles). (The CO2 conversion coefficient value is used by Tokyo Electric Power Company according to emission coefficients for each electric power supplier by the Ministry of the Environment in 2010.)

Reduction of CO2 emission amount

Compared to our previous models, a reduction of 356 kg/year in CO2 emissions is realized by reducing power consumption. The reduction in CO2 emissions by the QuaPro-R contributes to our customer’s environmental activities. [*8FBR15C model]

The Japan Machinery Federation Presidential Award r tor the year 2012: The Japan Machinery Federation

The Excellent Energy Conserving Machinery Award is the awarding system established in 1980 by general incorporated association of The Japan Machinery Federation, to encourage and promote the development and dissemination of an outstanding energy conserving machinery. The award system has been consecutively carried out to date. Our firm was awarded The Japan Machinery Federation Presidential Awards for the contribution to the promotion of effective energy use through the development of QuaPro-R that achieved overwhelming energy saving.

Prolong of operating time

Prolong of approximately 2 hours in operating time compared to our previous models is realized by reducing power consumption. Auxiliary charging is reduced which provides advantages in various situations such as reductions in the entire operation time, or even continuous operation when unexpected additional work is required.

[*8FBR15C model]

(JIS D6202:2011 in-company test value occurring in operation cycle pattern)

QuaPro-R design concept: Integration of human and machine.

The inching ability of the QuaPro-R during travel and load handling has been thoroughly revised to realize spontaneous operation in response to the operator’s intentions. Moreover, operator-oriented vehicle manufacturing has been conducted for easy getting on and off by lowering the floor while maintaining good mast visibility. The integrated human-machine operation feel enhances load handling efficiency, and leads to overall productivity improvement. In addition, AWC (small turn radius control) is equipped to realize its key concept of a minimum turning diameter (minimum right-angle stacking aisle width). Selection to minimize 90-degree turning (stacking mode) during load handling can be performed freely.

The QuaPro-R pursues a comfortable operation feel that goes one step further.

Electric Reach Forklift Trucks

QuaPro-R

Electric Reach Forklift Trucks

Human-Machine integrated operation feel

Intuitive operation feel in responding to the operator’s intentions.

Human Sensible

Stacking mode, minimizing the right-angle stacking aisle width, can be selected at a touch. In-place turns / turning mode, minimizing the turning radius during U-turns, also can be selected at a touch. In stacking mode, the optimum steering angle and axis of rotation are applied automatically to minimize the right-angle stacking aisle width. Being assisted by these features, the operator can make turns at the minimum right-angle stacking aisle width simply by turning the steering wheel to the maximum steering end without minding the optimum steering angle.

By revising the previous accelerator and acceleration characteristics, smooth and comfortable speed control range from low to high is realized. When fast acceleration is required, the vehicle can be accelerated quickly, and when performing fine inching operations, moderate acceleration and acceleration characteristics responding to conditions are realized.

By expanding the low speed range of the lift valve, an easy-to-use characteristic which enhances inching operations during load handling is realized. Moreover, by switching the load handling motor to an AC motor and optimizing the control during motor start-up, inching performance is improved and good response has been achieved.

Comfortable cabin space for ease of operation

To tap the machine’s true performance, maintaining a comfortable cabin where the operator comes into contact is essential. Comfort in getting on and off the cabin space has been enhanced over previous models with meticulous consideration made for the areas where the operator and machine come into contact such as the floor and operation panel.

Comfortable fit for operator

Comfortable fit for operatorSurround cockpit

A round shaped operator space which wraps flexibly around the operator has been adopted while maintaining the easy-to-operate lever type layout. The parts of the operation space which the operator contacts are curved in shape and are designed to provide a natural body fit feel.

The photographs have been shot for the catalog. In actual model, caution labels are adhered to specified areas.

Visor-integrated display

Visor-integrated display

A visor has been newly added to the top of the display to prevent reflected glare and improve visibility. In addition, the display surface is set an angle facing the operator allowing verification of the display using a natural field of vision.

Low vibration suspension system

The QuaPro-R has adopted a parallel link type structure. Compared to previous models, this structure greatly minimized uncomfortable vibrations from the floor surface, reducing fatigue of the operator. In addition, a suspension lock mechanism has been added to improve stability during turning and load handling, improving both comfort and safety at a higher level.

QuaPro-R

Electric Reach Forklift Trucks

45 mm compare to previous models.

Lowered floor

The QuaPro-R has the lowest floor height of 250 mm that tops the industry, -45 mm compare to previous models. This contributes to reduced operator fatigue in reach-forklift truck work with its frequent getting on and off.

Back support High-back support

A back support (supports the operator’s back) and a high-back support (supports the shoulders from the sides) are newly adopted. Support during switchbacks from reverse to forward is provided, and fatigue during normal operation is reduced.

The back support can be adjusted in the vertical direction.

Equipment and mechanisms for ensuring safety of operators

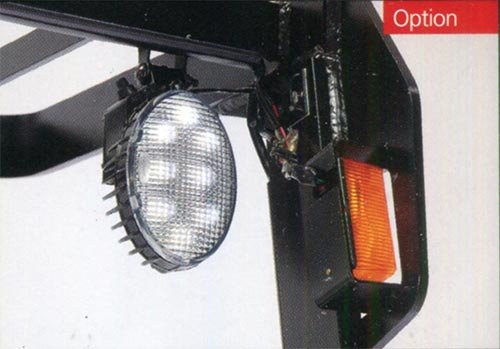

The QuaPro-R has various safety mechanisms and equipment to ensure the safety of operators during travel and load handling operations. In addition, to ensure the safe operation in high, dark places, various options are available such as LED illumination, a carriage light, and a safety laser.

Prevents operator’s body from protruding

Prevents operator’s body from protruding

Elbow guard

The elbow guard covers the right side of the forklift to prevent the operator from protruding, and protecting the operator from becoming inadvertently pinned.

Turn speed control

The torque of the travel motor is controlled according to the amount of steering operation. As a result, dangerous acceleration is restricted while the forklift is turning, preventing hazardous situations such as rollover. In addition, unnecessary acceleration is prevented, this contributes to energy conservation. The control is optimized according to the amount of steering operation, therefore operability is not sacrificed.

Optimum control of down-slope speed

Optimum control of down-slope speed

Slope speed limiter

The slope speed limiter, which restricts unwanted acceleration on down-slopes, is standard equipment. The control records the speed when the accelerator pedal is in the neutral position and maintains a constant speed on a down-slope.

Prevents rollback on upslopes

Prevents rollback on upslopes

Anti-rollback

The anti-rollback mechanism, which prevents the forklift from rolling back when it starts from a stop on an upslope, is standard equipment.

Safety lock during operator’s absence

Safety lock during operator’s absence

Travel and load handling interlock

Travel and load handling operations are locked while the operator is away. The presence or non-presence of the operator is detected by the riding sensor, operation from outside the forklift is locked even when the key is on. While the load handling operations are locked, lift-down operation is locked.

Front wheel brake anti-skid control

The front-wheel brakes comes into assist if the drive tires slip. This control prevents the tires from been locked and provides maximum brake force, the forklift is stabilized and the braking distance is minimized.Traction control

Slipping during starts and acceleration is prevented and the optimum traction force is transmitted to the ground.Sway due to slipping is prevented and optimum acceleration is obtained even on a slippery surface. (These two controls are a set option)Qua Pro-R

Electric Reach Forklift Trucks

Illumination equipment for safe operation

LED headlight (3-LED type)

The compact headlight does not reduce the visibility and overhead space. An automatic dimming function is not available. (Power consumption: 7.2 W)

LED auto-light (Illuminance sensing type)

he 8-LED type light illuminates in a wider area. This environmental-spec illumination automatically dims according to the surrounding brightness. (Power consumption: 19.2 W/4.8 W (dimmed))

Carriage light

A front light is newly equipped on the carriage. The load (fork insertion point) and rack are directly illuminated, load handling operations can be performed more safely.

Safety laser

When the forks are detected as being horizontal, horizontal lasers are projected into the insertion holes on the pallet. The operator can determine the fork insertion height accurately and safely. This enhance the efficient of the operation.

Maintenance cost reduction

The QuaPro-R also fulfills the functions with maintènance. It is designed with consideration for maintenance cost reduction using innovative mechanisms to reduce maintenance-related waste, as well as the addition of various information functions for easy maintenance.

Standard display

- Digital clock (alarm function)

- Remaining battery display

- Power mode level display

- Hour meter display (total time/key ON time/travel time)

- Speed limiter setting display

- Forklift operation maintenance data (total time *for 5 days)

- AWC mode display

- Operator setting mode display

Standard display

Full-function display

Function/display added to standard display- Digital clock (year, month, date, day/AM, PM/alarm function)

- Hour meter display (total time/key ON time/travel time/load operation time/distance)

- Speed limiter setting display (show set speed)

- Forklift operation maintenance data (total time/battery charge time/travel time/load operation time/distance *for 9 days)

Option

Full-function display-unique options- Password entry

- PCS (Shock-less load operation, Automatic lift stop, Automatic horizontal stop)

BDI interrupt (over-discharge load handling lock)

When the remaining battery is about 20%, a warning message will be shown on the display and the lifting speed is reduced. If the operation is continued, the lifting operation will be stopped to prevent battery over-discharge.

* Recharge the battery immediately when the warning indication is illuminated.

Mechanisms for cost reduction

IPM motor

Compact and highly efficient IPM motor which is also used on electrical automobile, is adopted for the travel motor.

The IPM motor has high dust-proof performance which eliminates grease shortage malfunctions and contributes in reducing maintenance costs.

AC motor for load handling

An AC motor is adopted for the load handling motor, its high efficiency contributes to energy conservation. Parts which wear out such as brushes and contactors are unnecessary. This contributes in reducing maintenance cost.

Qua Pro-R

Electric Reach Forklift Trucks

Plenty of variations are available.

Select the appropriate model matching the type of work and environment.

Variation

[Photo : 8FBR15C3]

Fisheries-use & freezer spec./Other special-spec, models

Fisheries-use spec. model

This type is suitable for operations which handle fishery and water-related products. Highly reliable forklift with enhanced anti-moisture and anti-rust countermeasures provides high resistance against water leakage and rust.

Freezer/refrigerator spec, model

This type assures load handling performance, travel performance and energy-conservation effects even under cold temperature conditions, and performs well in freezers and refrigerators of frozen food companies.

Fishery-product freezer/ refrigerator spec, model

This type has a full water/cold resistance mechanism and performs well flexibly in freezers and refrigerators of fishery-processing companies.

Select the desired battery removal mode based on your maintenance requirements and frequency.

Front battery removal

The battery can be removed by simultaneously operating the key and the battery lock release pedal.Water refilling, inspection and replacement can be performed easily, contributing to reduced maintenance time.

Thorough consideration for safety is made such as auto travel-stop while performing maintenance and, of course, mis-operation prevention.

Side battery removal

The battery can be pulled out easily from the side by opening the cover on the side of the vehicle with only a single touch. This also provides flexibililty at job sites requiring frequent battery changes.

Specifications

|

Model/Type/Battery Pullout type Item /Symbol |

1.0 ton |

1.25 ton |

1.35 ton | ||||

|

8FBR10 S(J)XII |

8FBR13 S(J)XII |

8FBR14 S(J)XII | |||||

|

type-S |

typeS |

typeS | |||||

|

Front Side |

Front Side |

Front Side | |||||

|

Performance |

Maximum load capacity |

kg |

1,000 |

1,250 |

1,350 | ||

|

Standard load center |

mm |

500 |

500 |

500 | |||

|

Standard lifting height |

mm |

E |

3,000 |

3,000 |

3,000 | ||

|

Free lift |

mm |

F |

113 |

113 |

113 | ||

|

Reach stroke |

mm |

455 | 440 |

595 580 |

595 580 | |||

|

Tilting angle (up/down) |

deg |

G/H |

50/30 |

50/30 |

50/30 | ||

|

Travel speed |

(Laden) |

km/h |

9.5 |

9.5 |

9.5 | ||

|

(Unladen) |

km/h |

11.0 |

11.0 |

11.0 | |||

|

Lifting speed |

(Laden) |

mm/s |

360 |

340 |

320 | ||

|

(Unladen) |

mm/s |

560 |

560 |

560 | |||

|

Minimum turning radius (outer) |

mm |

I |

1,360 |

1,495 |

1,495 | ||

|

Dimensions |

Overall length (with fork) |

mm |

A+K |

1,840 1,855 |

1,920 1,935 |

1,920 | 1,935 | |

|

Overall width |

mm |

L |

1,090 |

1,090 |

1,090 | ||

|

Mast lowered height |

mm |

B |

1,995 |

1,995 |

1,995 | ||

|

Max mast height w/backrest |

mm |

N |

3,935 |

3,935 |

3,935 | ||

|

Head guard height |

mm |

M |

2,240 |

2,240 |

2,240 | ||

|

Step height |

mm |

S |

250 |

250 |

250 | ||

|

Fork length |

mm |

A |

770 |

850 |

850 | ||

|

Fork spread width (maximum) |

mm |

D |

725 |

725 |

725 | ||

|

Fork spread width (minimum) |

mm |

C |

290 |

290 |

290 | ||

|

Wheel base |

mm |

0 |

1,110 |

1,250 |

1,250 | ||

|

Tread (front/rear) |

mm |

P/Q |

980/640 |

980/640 |

990/640 | ||

|

Minimum ground clearance |

mm |

R |

70 |

70 |

70 | ||

|

Vehicle weight |

kg |

2,035 |

2,095 |

2,140 | |||

|

Tires |

Front wheel |

Rubber; </>255X114 |

Rubber; </>255x114 |

Urethane; </>254x102 | |||

|

Drive wheel |

Rubber; </>330X145 |

Rubber; </>330X145 |

Rubber; </>330x145 | ||||

|

Caster wheel |

Rubber; </>150x80 |

Rubber; </>150x80 |

Rubber; </>150X80 | ||||

|

Electrical components |

Travel |

Control type |

FET inverter |

FET inverter |

FET inverter | ||

|

Output |

kW |

4.5 |

4.5 |

4.5 | |||

|

Hoist |

Control type |

FET inverter |

FET inverter |

FET inverter | |||

|

Output |

kW |

9.6 |

9.6 |

9.6 | |||

|

Steering |

Control type |

FET chopper |

FET chopper |

FET chopper | |||

|

Output |

kW |

0.3 |

0.3 |

0.3 | |||

|

Rechargeable battery |

Voltage X Capacity |

VxAh |

48/201 |

48/201 |

48/201 | ||

* Front: Front battery removal Side : Side battery removal

Main Accessories

|

Standard specs/accessories |

Optional specs / accessories |

Standard specs/accessories |

Optional specs/accessories | ||||

|

Workability |

Hoist related |

Hoist AC motor Soft landing High-visibility wide mast |

Lift/tilt/reach-speed limiter PCS *1 Simple load weight scale |

Safety |

Neutral start Slope speed limiter Anti-rollback Volume adjustable type reversing buzzer |

Elbow guard Rear rubber bumper Rear bumper (floor elongation shape) Forward/back movement chimer Forward/back melodic chimer | |

|

Steering related |

Suspension lock control AWC (small radius turning control) Small diameter steering wheel |

Large diameter steering wheel | |||||

|

Economy |

Display *2 |

LCD display |

Full function display (Full-dot LCD) | ||||

|

Travel related |

Travel IPM motor Neutral brake switchback regeneration Travel speed/power adjustment/speed limiter |

Speed limiter Head guard low overall height type |

Battery |

BDI interrupt (stop hoisting at over discharging) Auto power off |

Spare battery Battery carrier | ||

|

Lamp related |

Headlights Turning indicators |

LED headlights LED auto lights (light sensitive type) Safety laser Carriage light LED rotating light LED work light LED room light |

Environmental specs. |

Fisheries use spec. (Up to-I0°c) General freezer refrigerator spec. (Upto-35X /-45"C) Fisheries use freezer refrigerator spec (Up to -35t: /-45”C) Anti-rust spec. Anti-dust spec. | |||

|

Comfortability |

Low vibration suspension system Shock-less steering Low floor Waist band Manifest clip |

Back support High-back support Acrylic top cover |

* 1: Performs shock-less start to finish loading /unloading, auto-stop at maximum height, and horizontal auto-stop. *2: For the standard display/full function display function details, refer to the Cost Efficiency page (page 11). | ||||

|

Safety |

Turning speed control Travel and load handling interlock |

Anti-skid traction control Front protector | |||||

|

1.5 ton |

1.8 ton | |||||

|

8FBR15 C(J)XII |

8FBR15 S(J)XII |

8FBR15 A(J)XII |

8FBR15 W(J)XII |

8FBR18 S(J)XII |

8FBR18 A(J)XII |

8FBR18 W(J)XII |

|

typeC |

typeS |

type A |

type W |

typeS |

type A |

typeW |

|

Front Side |

Front Side |

Front Side |

Front Side |

Front Side |

Front Side |

Front Side |

|

1,500 |

1,500 |

1,500 |

1,500 |

1,800 |

1,800 |

1,800 |

|

500 |

500 |

500 |

500 |

500 |

500 |

500 |

|

3,000 |

3,000 |

4,000 |

4,000 |

3,000 |

4,000 |

4,000 |

|

113 |

113 |

113 |

995 |

113 |

113 |

995 |

|

660 |

595 |

770 |

705 |

770 |

770 |

705 |

|

573° |

573° |

573° |

573° |

573° |

573° |

573° , |

|

9.0 |

9.0 |

9.0 |

9.0 |

9.0 |

9.0 |

9.0 |

|

10.5 |

10.5 |

10.5 |

10.5 |

10.5 |

10.5 |

10.5 |

|

310 |

310 |

310 |

280 |

280 |

280 |

250 |

|

560 |

560 |

560 |

470 |

560 |

560 |

450 |

|

1,580 |

1,580 |

1,755 |

1,755 |

1,755 |

1,785 |

1,755 |

|

2,015 |

2,080 |

2,080 |

2,145 |

2,080 |

2,110 |

2,145 |

|

1,090 |

1,090 |

1,090 |

1,190 |

1,090 |

1,090 |

1,190 |

|

1,995 |

1,995 |

2,495 |

1,895 |

1,995 |

2,495 |

1,895 |

|

3,935 |

3,935 |

4,935 |

4,925 |

3,935 |

4,935 |

4,925 |

|

2,240 |

2,240 |

2,240 |

2,240 |

2,240 |

2,240 |

2,240 |

|

250 |

250 |

250 |

250 |

250 |

250 |

250 |

|

920 |

920 |

920 |

920 |

920 |

920 |

920 |

|

725 |

725 |

725 |

825 |

725 |

725 |

825 |

|

290 |

290 |

290 |

290 |

290 |

290 |

290 |

|

1,340 |

1,340 |

1,515 |

1,515 |

1,515 |

1,515 |

1,515 |

|

990/640 |

990/640 |

990/640 |

1,090/640 |

990/640 |

990/640 |

1,090/640 |

|

70 |

70 |

70 |

70 |

70 |

70 |

70 |

|

2,225 |

2,230 |

2,315 |

2,335 |

2,315 |

2,415 |

2,435 |

|

Urethane;<*>2 54x102 |

Urethane; <*>254X102 |

Urethane; <*>254x102 | ||||

|

Rubber; <*>330x145 |

Rubber; <*>330x145 |

Rubber; <*>330x145 | ||||

|

Rubber; <*>150x80 |

Rubber; <*>150X80 |

Rubber; <*>150X80 | ||||

|

FET inverter |

FET inverter |

FET inverter | ||||

|

4.5 |

4.5 |

4.5 | ||||

|

FET inverter |

FET inverter |

FET inverter | ||||

|

9.6 |

9.6 |

9.6 | ||||

|

FET chopper |

FET chopper |

FET chopper | ||||

|

0.3 |

0.3 |

0.3 | ||||

|

48/260 |

48/280 |

48/280 | ||||

Dimension Chat

Load Capacity Chats